VRHUNSKA

NATANČNOST

PROTOTIPI

Nudimo specializirano proizvodnjo prototipov, kar strankam omogoča, da testirajo in preverijo oblikovanje, preden začnejo s serijsko proizvodnjo. Ta storitev zagotavlja, da vsak del komponente izpolnjuje natančne specifikacije, zmanjšuje tveganja in optimizira proizvodnjo za visoko kakovost. Naš postopek prototipov omogoča strankam učinkovit in zanesljiv prehod od ideje do končnega izdelka.

NAČRTOVANJE ORODIJ IN PROCESOV

Naša ekipa tesno sodeluje s strankami, da razumemo njihove specifične zahteve, razvijemo prilagojena orodja in optimiziramo procese za vsak projekt. Na ta način vsak postopek finega štancanja doseže najvišjo raven natančnosti, učinkovitosti in dosledne kakovosti.

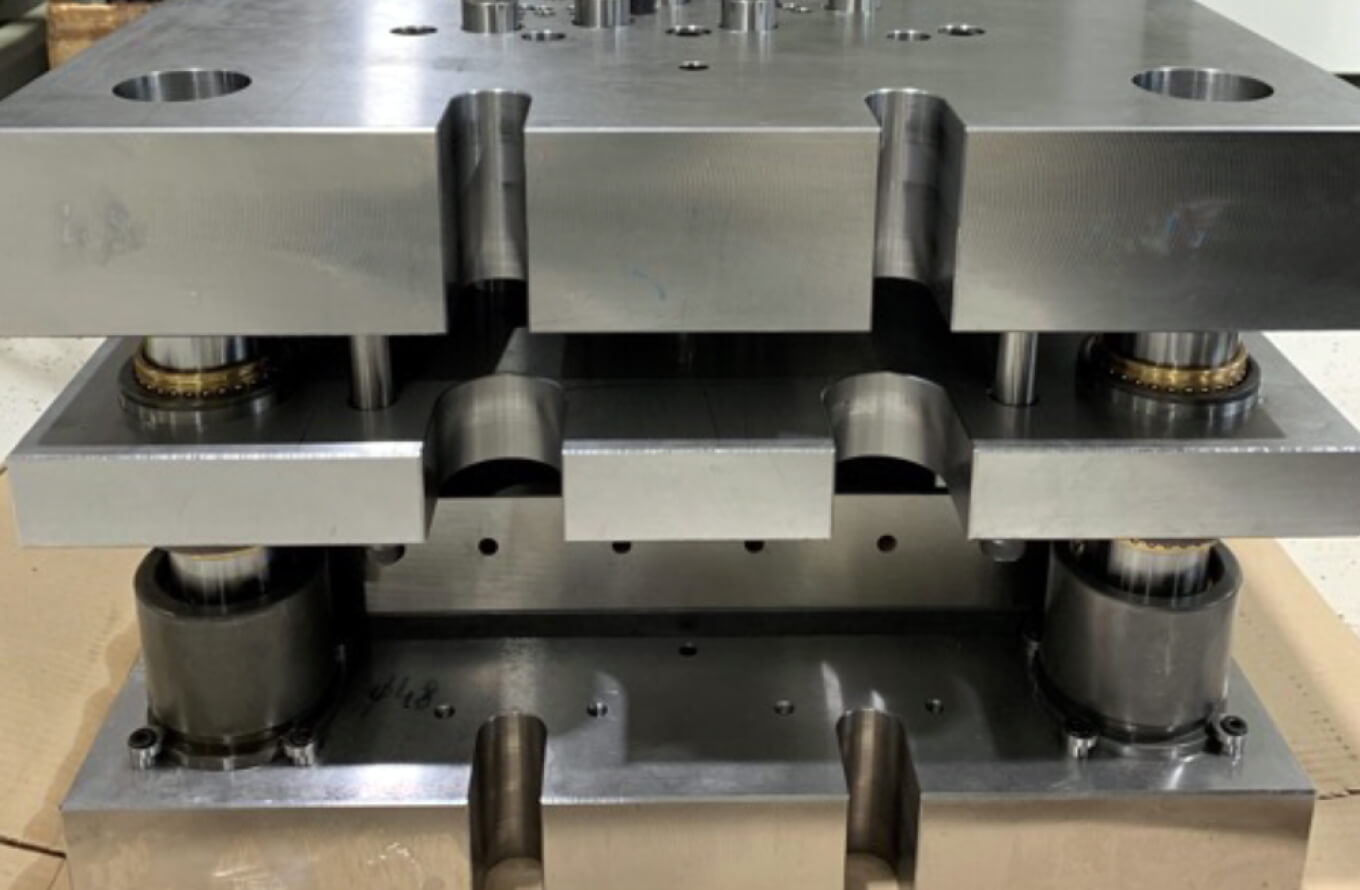

OBLIKOVANJE ORODIJ

Kompleksna storitev načrtovanja orodij za fino štancanje so ključnega pomena za naše poslovanje. Naši strokovnjaki v podjetju ustvarjajo prilagojena orodja, ki so zasnovana posebej za vsak projekt, kar zagotavlja optimalno delovanje in natančnost. Ta specializirana orodja zagotavljajo visoko kakovostno proizvodnjo z ozkimi tolerancami in učinkovitostjo že od samega začetka.

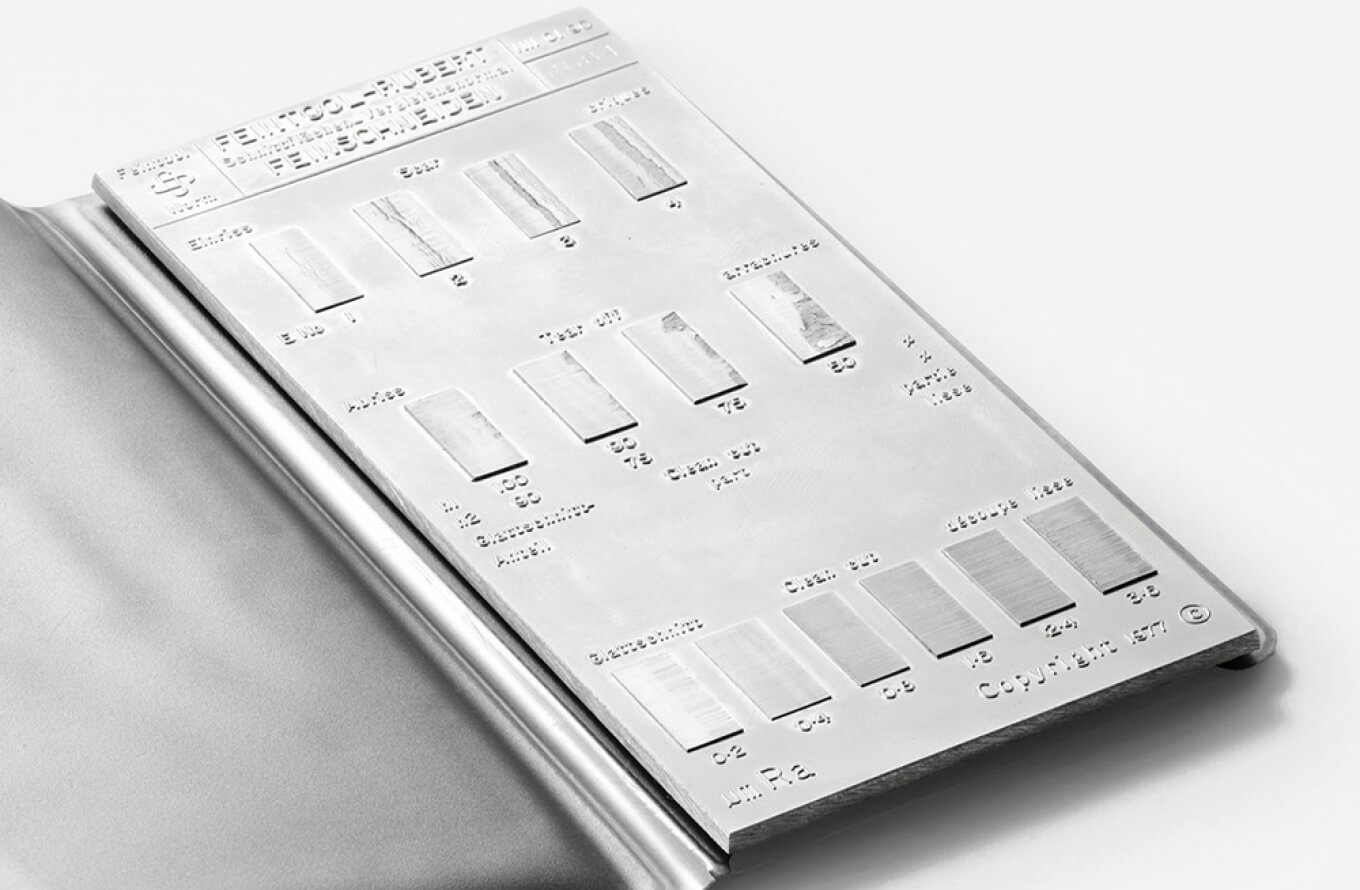

NATANČNOST ORODIJ

Preciznost orodij je ključna v industriji finega štancanja, saj neposredno vpliva na natančnost, kakovost in doslednost proizvedenih komponent. Visoko natančna orodja omogočajo ozke tolerance in čiste robove, kar zagotavlja zanesljive in brez napak izdelane dele, ki izpolnjujejo najvišje standarde.

FINO ŠTANCANJE

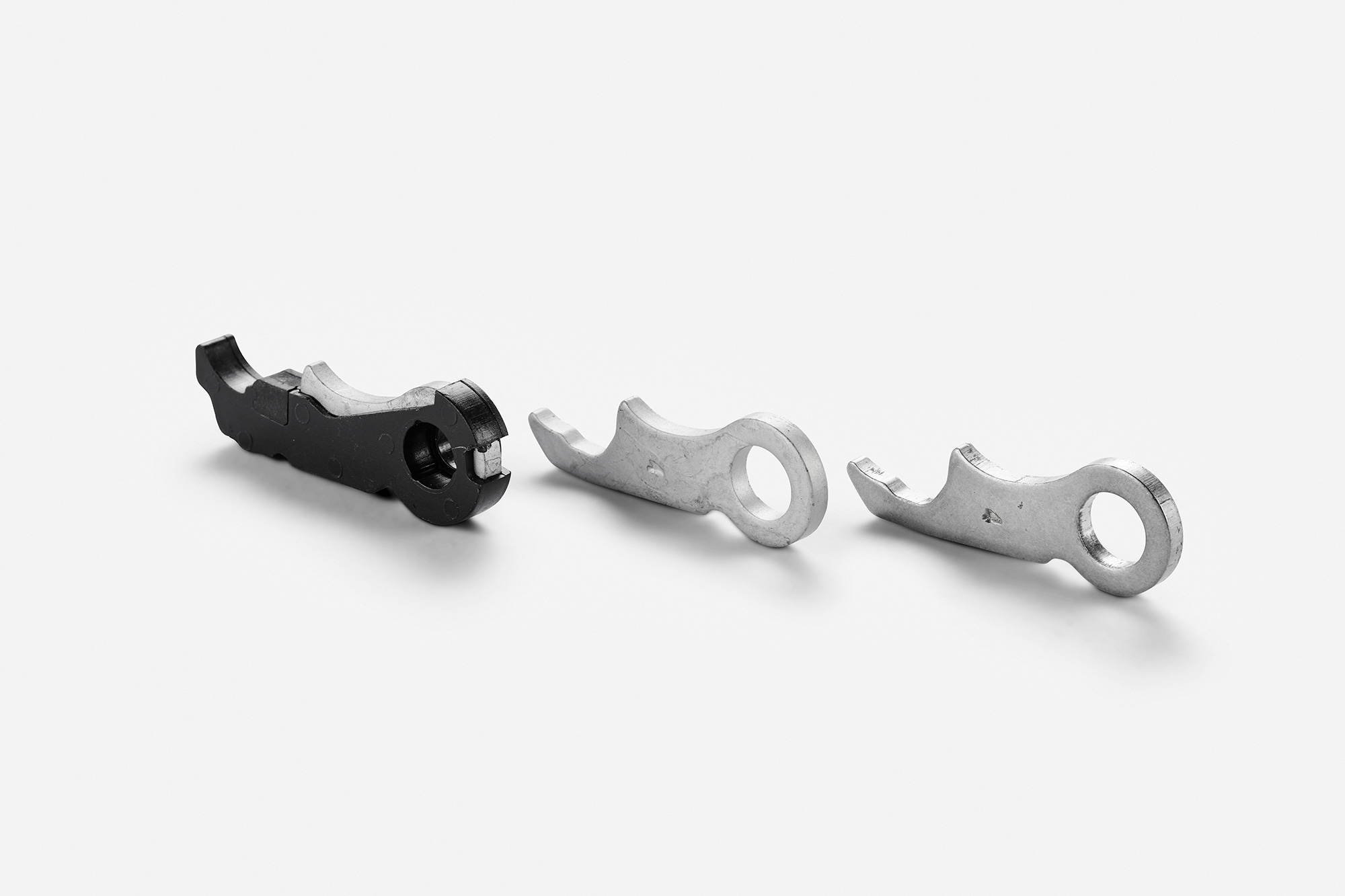

Težimo k odličnosti z zagotavljanjem najkakovostnejših, natančnih komponent, prilagojenih zahtevam zahtevnih industrij. Z uporabo najsodobnejših strojev in izpopolnjenih tehnik proizvajamo dele s kompleksnimi geometrijami in stanjem robov brez srha. Naša predanost natančnosti nam omogoča dosego ozkih toleranc in izjemne kakovosti površine, zaradi česar smo zanesljiv partner.

PROIZVODNJA

Imamo proizvodne linije, ki jih poganjajo FEINTOOL stroji, kar nam omogoča proizvodnjo visoko natančnih delov z izjemnimi podrobnostmi. Naša ekipa zagotavlja dosledno kakovost in učinkovitost, kar nam omogoča izpolnjevanje strogih zahtev različnih industrij s pomočjo zanesljivih, brez napak izdelanih komponent.

RAZIGLANJE, KALJENJE IN POVRŠINSKA OBDELAVA

Zadnje možnosti dokončanja vključujejo raziglanje za gladke in robove brez napak, toplotno obdelavo za povečanje trdnosti in vzdržljivosti ter površinsko obdelavo za zaščito pred obrabo in korozijo. Ti zaključni koraki izboljšujejo delovanje, zanesljivost in dolgo življenjsko dobo.

ZABRIZGAVANJE

Injekcijsko zabrizgavanje nadgradi izdelke finega štancanja z dodajanjem sloja oblikovanega materiala, ki izboljšuje funkcionalnost, vzdržljivost in estetiko. Proces omogoča integracijo različnih materialov, s čimer odpira možnosti za kompleksne zasnove in dodatne funkcionalnosti, prilagojene specifičnim zahtevam.

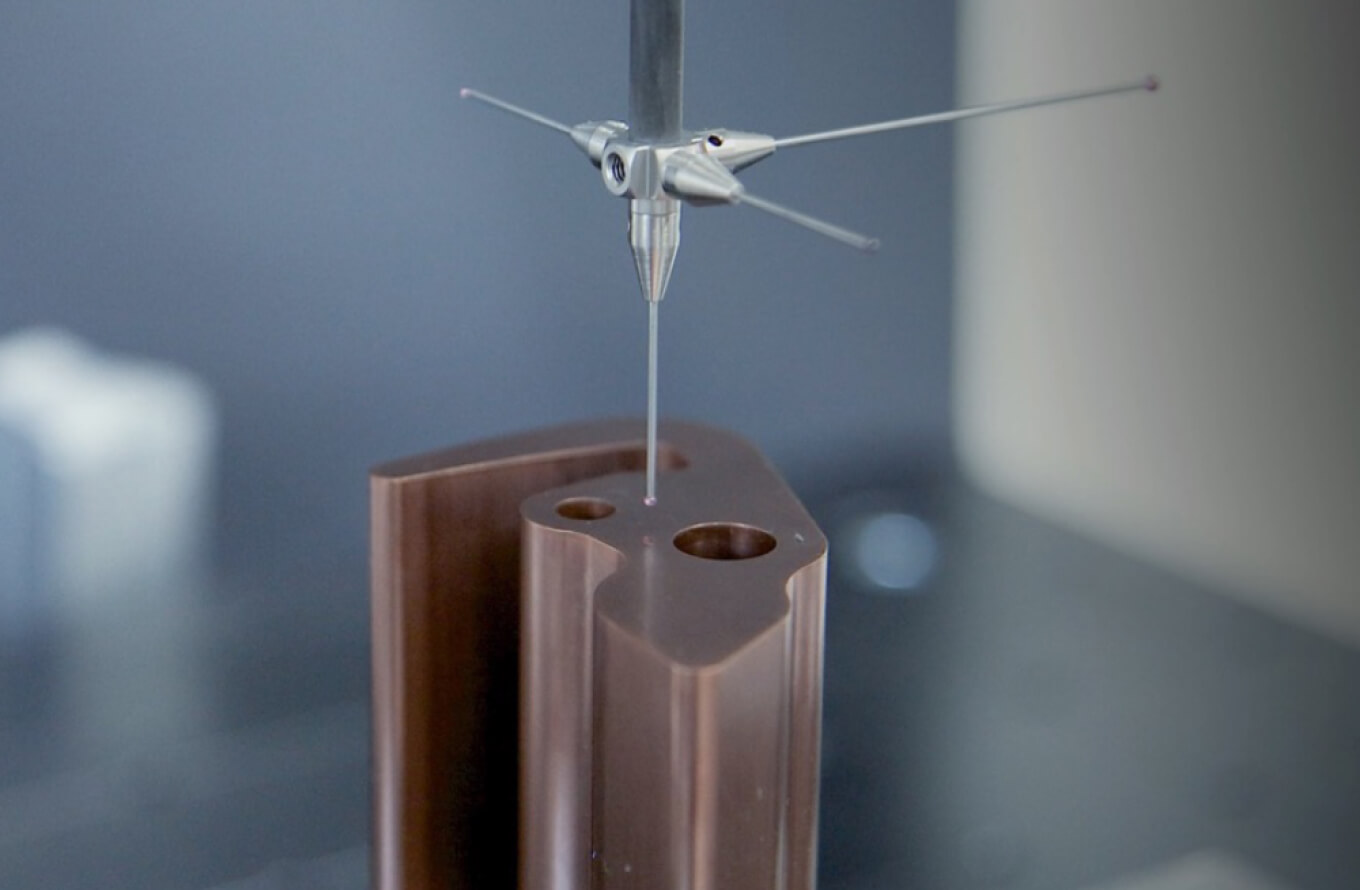

MERITVE IN KONTROLA KAKOVOSTI

Precizne meritve in rigorozna kontrola kakovosti sta ključni za zagotavljanje, da komponente izpolnjujejo natančne specifikacije. Pri Tim Pavlin uporabljamo napredna orodja za pregled in testirne procese za preverjanje dimenzij, toleranc in kakovosti površine, kar zagotavlja izdelke brez napak, ki izpolnjujejo najvišje standarde.

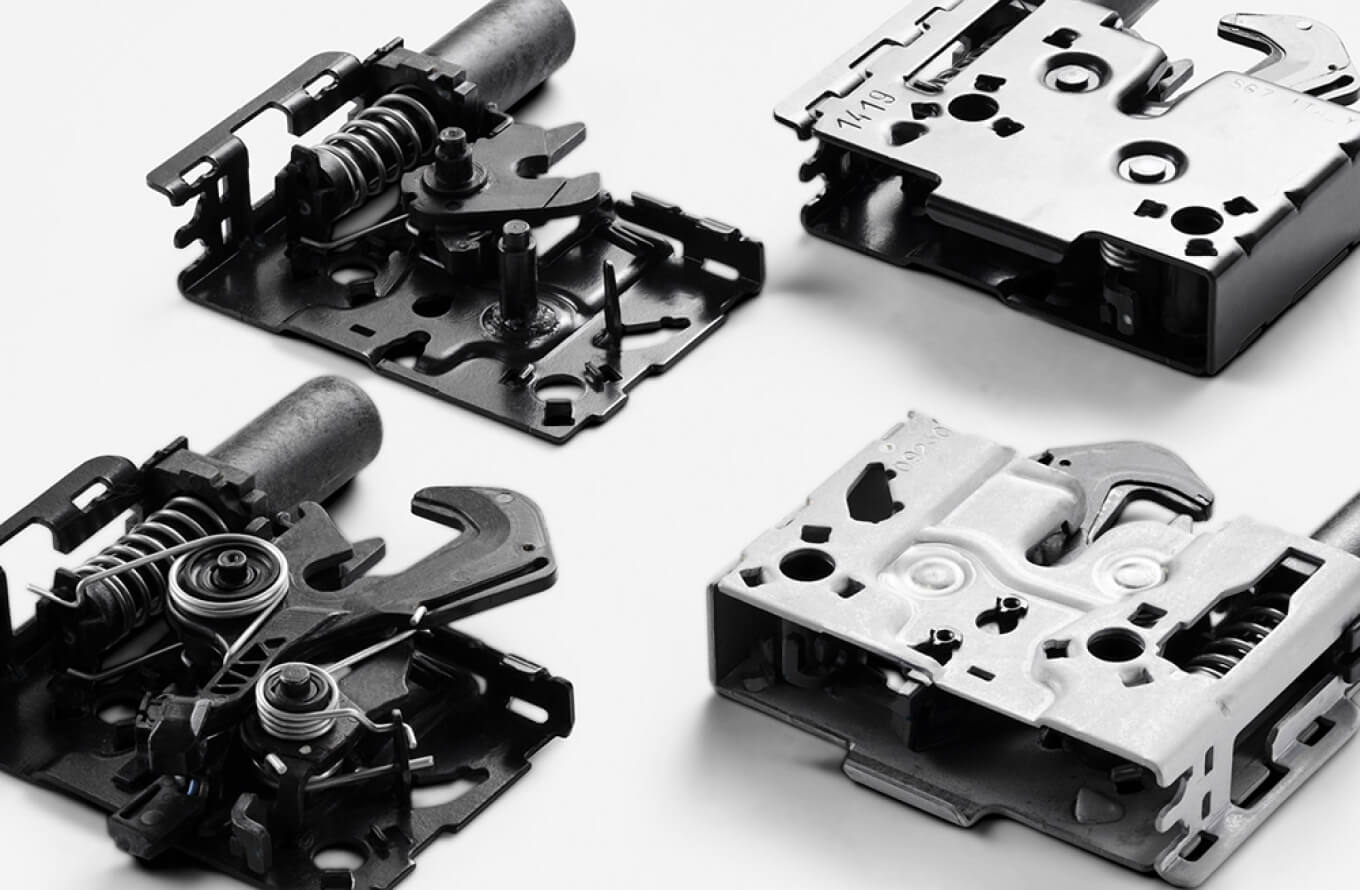

NAŠI IZDELKI V SKLOPIH

Sodelujemo s strankami, ki integrirajo proizvedene dele finega štancanja v sklope. Z usklajevanjem s potrebami oblikovanja in funkcionalnosti zagotavljamo, da vsaka komponenta prispeva k učinkovitosti, zanesljivosti in delovanju končnega sistema in funkcije.